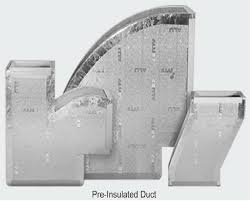

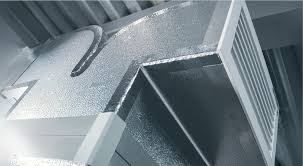

Specifications of Pre-insulated air ducts

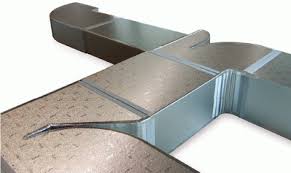

- Pre-insulated ducting is airtight, in which it improves system efficiency and reduces running cost. This is due to tight connection between joints preventing any possible air leak.

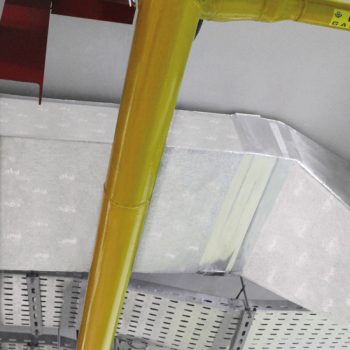

- Pre-Insulated Ducts are light weighted yet strong enough to hold the handling in sites and during installation and can keep its dimensional stability for years.

- The density and rigidity of Pre-insulated ducting ensures less of vibration and reduces noise level.

- No corrosion

- High chemical, acid, bacteria, parasite, ant and mildew resistance

- Pre-insulated ducts can be fabricated quickly and most of the time at site and can be installed with minimum efforts and manpower

- Higher resistance in case of Fire.

- Easy maintenance

- Durability + 50 years

- No safety hazards or loose particles

- Both sides Covered with Aluminum layer